Do You Know How to Choose Proper Bearing Clearance 2020? [Quick]

Do You Know How to Choose Proper Bearing Clearance 2020? [Quick]

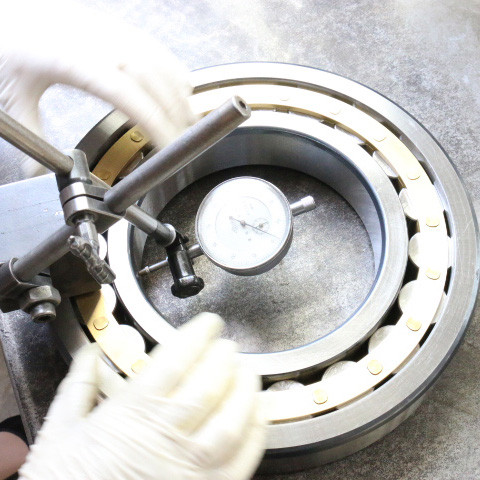

Bearing clearance is the gap between the bearing rolling element and the bearing inner and outer ring shells. It refers to the amount of the bearing movement when it doesn't at the shaft or bearing housing. And the inner ring or the outer ring is fixed, and then the clearance is not fixed.

According to the moving direction, it has two types are radial and axial clearance. The bearing play size during operation has an effect on the rolling fatigue life, temperature rise, noise, vibration, and other properties of the bearing.

In the same way as bearing lubrication, excessive or too little grease will cause bearing temperature changes, resulting in bearing damage. Similarly, the bearing play is too large or too small, it will reduce the bearing's working life and even the stability of the entire equipment operation.

Bearing Clearance Types

Installation clearance

When you mount the bearing on the shaft or in the casing. The amount of expansion of the ferrule or the bearing play after contraction due to the interference fit. We call it "installation clearance".

Effective clearance (Working clearance)

Effective clearance refers to the actual windage existing in the bearing. After installing the bearing in the host and under a certain load to achieve a certain temperature rise and stable operation. Obviously, the effective clearance is smaller than the original clearance.

Working play refers to the clearance under the actual operating conditions of the bearing.

When the working play is slightly negative, the rolling bearing has the longest fatigue life. However, as the negative clearance increases, fatigue life decreases significantly. Therefore, when selecting a bearing play, the play is generally zero or slightly positive.

In addition, when it's necessary to increase the bearing rigidity or reduce the noise, the working play should further take a negative value. When the bearing temperature rises sharply, the working clearance should further take a positive value.

Importance of Bearing Clearance

In order to achieve the most ideal life, the bearing must have a suitable clearance. The clearance value = design clearance - the amount of clearance reduction caused by the inner ring fit - the outer ring clearance reduction due to the fit + (or -) the amount of clearance reduction (or increase) due to the temperature difference.

The choice of specific clearance depends on the technical standards for equipment installation.