How to Choose A Double Direction Tapered Roller Thrust Bearing

How to Choose A Double Direction Tapered Roller Thrust Bearing

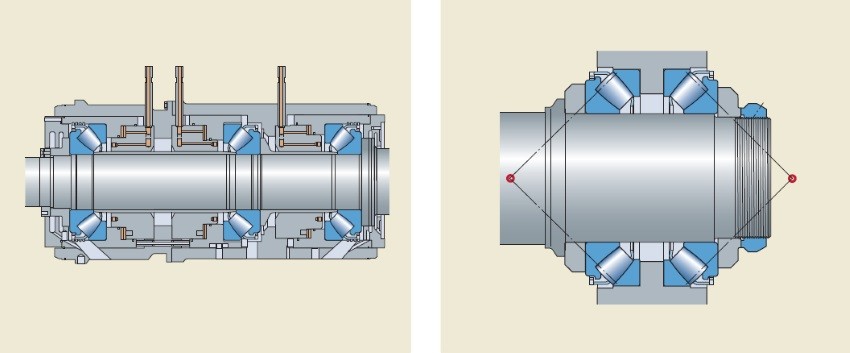

Structure

Bidirectional thrust tapered roller bearing bears centrifugal torque during operation. So the relative sliding occurs between the rolling elements and raceways, causing the shaft and race to separate. To ensure the normal operation of the bearing, it must apply a certain axial load.

They can bear axial loads from two directions, suitable for high-load occasions, and have high axial rigidity. Use a steel alloy car cage. Bidirectional double-row thrust cylindrical roller bearings do not allow the shaft incline with the axis of the housing. Larger angular alignment errors will generate additional stress and shorten the service life of the bearing. When the bidirectional double row thrust cylindrical roller bearing is in operation, the rolling elements are affected by the centrifugal torque, and relative sliding occurs between the rolling elements and the raceway, which will cause the shaft ring and the seat ring to separate. Therefore, in order to ensure the normal operation of the bearing, it must apply a certain axial load.