All Is about What Are Cylindrical Roller Bearings [Right Now]

All Is about What Are Cylindrical Roller Bearings [Right Now]

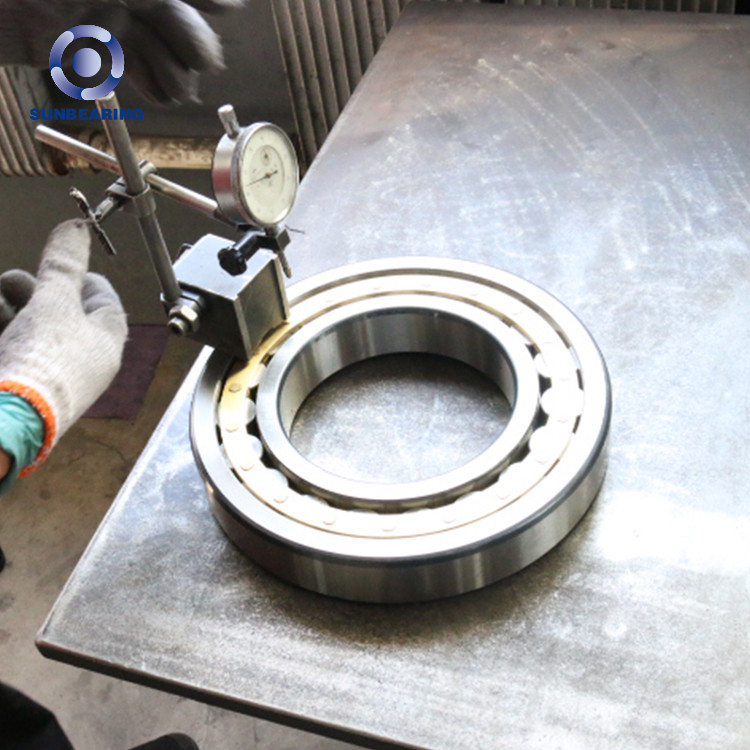

A cylindrical roller bearing is a bearing in which cylinders serve as rolling elements instead of balls in ball bearings. The rollers have a greater linear contact area with the outer ring and can distribute loads across a broader surface. The purpose of this bearing is to carry heavy radial loads.

Cylindrical roller bearings have a single row, two rows, or multi-rows of rolling elements. The different number of rolling elements is due to meet an application’s radial load requirement.

Since they are available in a number of standard series and configurations, cylindrical roller bearings have wide applications in many industries. The combination of moderate speed rating, industry interchangeability, and load capacity make it one of the most popular bearing designs.

The bearings have the ABMA series metric and inch, ISO series metric, Full Complement series, journal type, cluster mill sizes, and multi-row series.

Cylindrical roller bearings are dimensionally interchangeable to same numbered and sized bearings in the industry. The components of journal bearings and other standard series are interchangeable with other manufacturer’s components.

How Do Cylindrical Roller Bearing Work

Cylindrical roller bearings have modified line contact with cylindrical inner and outer ring raceways, ground ribs guide the rollers. This is either on the inner or outer ring.

The shape is a cylinder that makes it available for the inner ring to have axial movement relative to the outer ring. This is significant when you are dealing with thermal expansion, you should press-fit two of the rings.

With this bearing type, the cylindrical rollers are in linear contact with the raceways. They also have a high radial load capacity which is ideal for high speeds.

Roller Bearing Types

There are a number of types which are NU, NJ, NUP, N, NF for single-row bearings and NNU and NN for double-row bearings. This is in accordance with the design or absence of side ribs. Both of the inner and outer rings of every type are separable.

Some cylindrical roller bearings come with no ribs on both the inner and outer rings. Because of that, the rings are able to move axially relative to each other. People can use them as free-end bearings.

The type of cylindrical roller bearing where either the inner or outer ring has two ribs, or the outer ring has one, can take some axial load in one direction. Double-row cylindrical roller bearings have high radial rigidity, so people use them for precision machine tools.

Usually, people use pressed steel or machine brass cages but sometimes employ molded polyamide cages.

Dependent on the existence of the ribs on their rings, we can category cylindrical roller bearings with these types:

The types NH and NUP are fixed-end bearings, types NJ and NF can sustain limited axial loads in one direction, and types NU, N, NNU, and NN are good for free-end bearings.

NH-type cylindrical bearings possess the NJ-type cylindrical roller bearings and HJ-type L-shaped thrust collars. The inner ring loose rib of a NUP-type cylindrical bearing has to be mounted in order for the marked side to be on the outside.