How to Install Heavy Duty Roller Bearings on Equipment

How to Install Heavy Duty Roller Bearings on Equipment

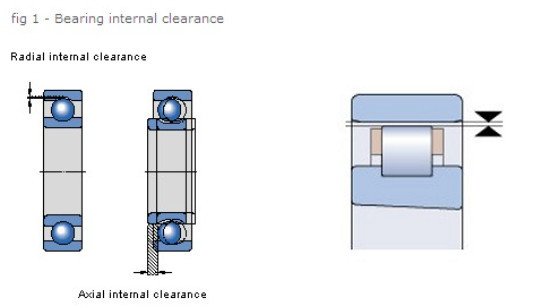

Bearing installation clearance

The clearance of a rolling bearing refers to the maximum amount of movement of the other ring in the radial or axial direction when one ring is fixed. Therefore, the clearance has two types which are radial clearance and axial clearance. When you assemble rolling bearings, ensure that the bearing clearance is moderate.

Too much clearance will affect the number of rolling elements bearing the load at the same time. This will increase a load of a single rolling element, thereby reducing the rotation accuracy of the bearing and reducing the service life.

Too small clearance will increase friction and generate more heat. This will aggravate the wear and also reduce the service life of the bearing. Therefore, many bearings must strictly control and adjust the clearance during assembly.

Bearing preload

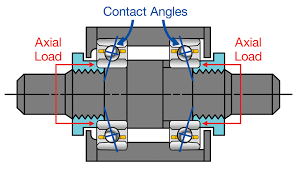

Bearing preload is when you are assembling the bearing, give an axial force to the inner or outer ring of the bearing. Use this method to eliminate the bearing clearance, and the initial deformation of the contact between the rolling elements and the inner and outer rings occurs. Preloading can improve the stiffness and rotation accuracy of the bearing under working conditions.

For bearings that bear large loads and require high rotation accuracy, most of them work in a state of no clearance or even a small amount of interference. In this case, you need to pre-tighten the bearing during assembly.