How to Install Sliding Bearings Correctly

How to Install Sliding Bearings Correctly

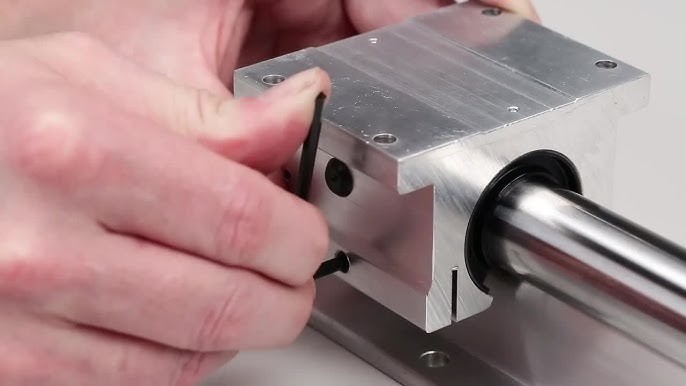

Assembly of integral sliding bearing

Integral sliding bearings have another name of shaft sleeves, and they are also the simplest form of sliding bearings. Mainly use press-in and hammering methods to assemble. Hot loading method for special occasions. Most of the bushings are made of copper or cast iron. You should take care of it when assembling. You can use a wooden hammer or a hammer to hit the wooden block to assemble. However, when the bearing has a large interference size tolerance, press it in with a press machine. Whether you knock-in or press in, you must prevent it from tilting. After assembly, the oil groove and oil hole should be in the required position.

If there is a distorted bearing after assembly, you should trim the inner hole. You can use a reamer to shave the smaller size and scrape the larger one. At the same time, pay attention to the clearance between the control and the shaft within the tolerance range. In order to prevent the shaft sleeve from rotating when it is working, you need to install a positioning pin or a seam screw on the contact surface between the shaft sleeve and the box body.

Assembly of split bearings

①Assembly of bearing bush and bearing body

You must keep the upper and lower bearing bushes in good contact with the inner hole of the bearing. If you use the bore of the thick-walled bearing bush as a reference, you need to scrape the back of the bearing bush. At the same time, you should make the two end steps of the bearing bush close to the two ends of the bearing body. Thin-walled bushes only need to make the middle parting surface of the bearing bush higher than the middle parting surface of the bearing body by about 0.1mm, without scraping.

②Position of bearing bush

Install the bearing bush into the bearing body. There is no permission for radial and axial displacement. People usually use the steps at both ends of the bearing bush to stop the positioning or locate the positioning pin.

③Scraping of bearing bush

The open-bearing bush is generally using a matching shaft grinding point. People usually scrape off the bearing bush first and then scrape the bearing bush. In order to improve efficiency, you don’t need to install the bearing shell and cover when scraping off the bearing shell. The tightness of the shaft increases with the number of scraping when you match the scraping, you can adjust it by changing the thickness of the gasket. After you tighten the bearing cap, the shaft can easily rotate without obvious gap, so that the contact point can meet the requirements, which means that the scraping is completed.

④Measurement of bearing clearance

You can determine the size of the bearing gap by adjusting the spacer at the center dividing surface, or by directly scraping the bearing bush. People usually use lead pressure method to measure bearing clearance. Generally, the clearance of the bearing should be 1.5‰-2.5‰ (mm) of the shaft diameter. The smaller the clearance value is when the diameter is larger. If the shaft diameter is 60mm, the bearing clearance should be between 0.09-0.15mm.