Complete Information You Want to Know about Fan Spindle Bearing 2021 [Quick]

Complete Information You Want to Know about Fan Spindle Bearing 2021 [Quick]

Brief Introduction of Fan Spindle Bearing

Fan spindle bearing is almost the most important component in a wind turbine. A wind turbine with a megawatt level or above will need 4 precision slewing bearings to support it. Namely, yaw support and three-pitch support. Because of the structure of the wind turbine. As well as 1 main shaft bearing and 1 Speed-increasing box spindle bearing.

At present, spindle bearings mainly include tapered roller bearings, spherical roller bearings, 2-3 row cylindrical roller bearings, etc. In order to make the bearings have a longer service life and stronger load-carrying capacity. Use multiple-row rollers more frequently.

Of all the wind turbines installed today, 75% to 80% adopt the principle of main shaft bearing support. That is, rotating the main shaft will install the inner ring. The main shaft supports the hub and blades and transmits torque to the speed increase.

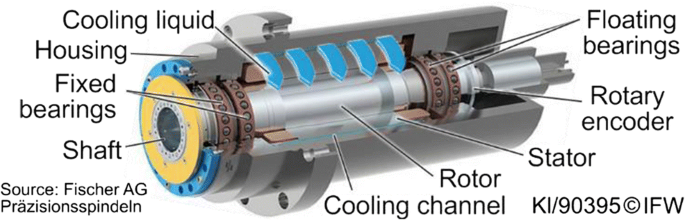

The main shaft bearing mainly bears radial force. Its performance not only affects the transmission efficiency but also determines the maintenance cost of the main drive chain. So that requires good centering performance, anti-vibration performance, and smooth running.

On the main shaft, a dual-bearing configuration is a common form of bearing configuration. The type of bearing used varies according to the design requirements. But the more common bearing configuration is a spherical roller bearing or a tapered roller match.

Configuration of cylindrical roller bearings. High-power wind turbines mostly use large cone-angle double-row tapered roller bearings or three-row cylindrical roller bearings.

The key technology of wind turbine main bearing manufacturing

Wind turbines work in the field all year round. The working conditions are relatively harsh, the temperature, humidity, and bearing load vary greatly, and there is an impact load. Therefore, the bearing requires good sealing performance and lubrication performance, impact resistance, long life, and high reliability.

The reliability of wind turbines requires more than 20 years, and as a supporting bearing. It also requires a service life of more than 20 years. The wind turbine must be started at 2-3 winds. And people need to design the bearing structure especially to ensure low friction and high sensitivity.

According to the force characteristics of bearing axial load, radial load, an impact load at the same time. Due to the involved multi-discipline, should pay special attention to the study of key technologies. Such as the optimization of materials used in the manufacture of bearing parts, material quality control, process measures, the life of extra-large bearings, and application.

Life needs to meet the established requirements of the fan

When selecting a wind turbine bearing supplier, a wind turbine manufacturer should not only inspect the supplier’s economic scale, management level, quality assurance ability, and product cost performance but also investigate its anti-fatigue manufacturing technology research and research in the production of wind turbine bearings. The situation of the application.

The wind turbine bearings of the same model produced by different manufacturers are almost identical in appearance. But the internal quality, life span, and reliability are sometimes far different.

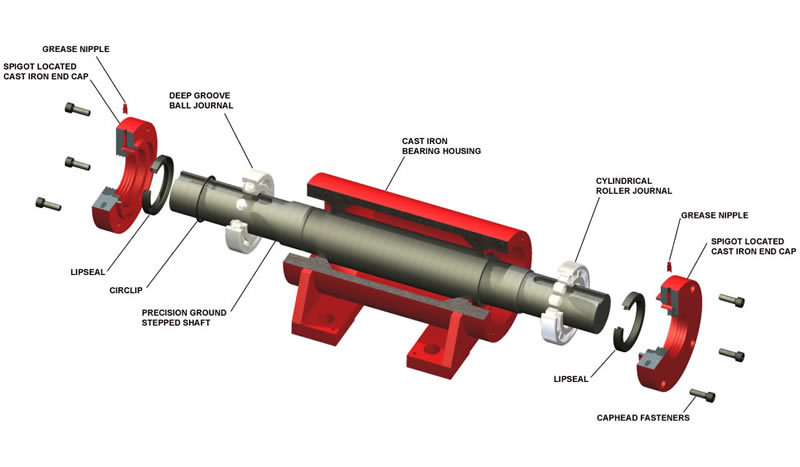

In addition to meeting the requirements of load and life, the main task of rolling bearing selection is to size the inner port, outer ring, and rolling elements. And to ensure that the radial clearance or width meets the requirements after assembly.

One of the main processes in the assembly process of rolling bearings is the selection of matching sleeves.

First, should select and group the raceway diameters of the rings. And then the inner ring, outer ring, and rolling elements of the various groups should be selected according to the required clearance. Or the width of the bearing tolerance fits together to become a "set" of bearings (belonging to the manufacturer's production process).

The necessary qualities of rolling bearings

When selecting a roller bearing, the clearance of the bearing, the modification of the roller, and the selection of lubricating oil should also be mainly considered.

Bearing lubrication, operating temperature and clearance have a great influence on its carrying capacity. Appropriate lubricant can provide good lubrication between bearing components. Especially in low-temperature conditions, the lubricating oil is required to have good viscosity-temperature characteristics, which can reduce the friction torque when the bearing is started, and at the same time, in order to prevent the lubricating oil film from being damaged.

To avoid direct contact between components. There will be a state of friction, the bearing will heat up and expand. And reduce the performance of the components. You can consider using centralized lubrication to lubricate the bearings to prevent the lack of lubrication due to the long refueling cycle, resulting in bearing damage.

Excessive bearing clearance can easily lead to a reduction in the number of rollers that bear external loads during operation. And aggravate pitting and wear of the rollers. Too small clearance can easily lead to higher friction and heating temperature of the bearing, destroying the oil film. And in many extreme conditions often only a few rollers are loaded. Therefore, the influence of bearing clearance on its life should be considered when designing and selecting.