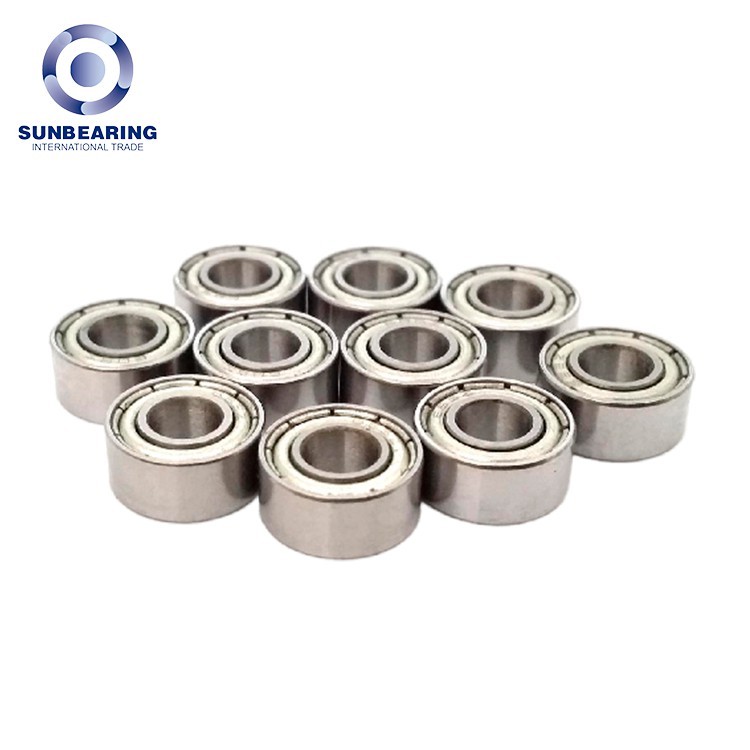

685 ZZ Minature Deep Groove Ball Bearing 5*11*3mm Chrome Steel SUNBEARING

685 ZZ Minature Deep Groove Ball Bearing 5*11*3mm Chrome Steel SUNBEARING

685 ZZ Minature Deep Groove Ball Bearing 5*11*3mm Chrome Steel SUNBEARING

|

Bore diameter:

|

5 mm

|

Basic dynamic load rating

|

0,715 kN |

|

Outside diameter:

|

11 mm

|

Basic static load rating

|

0,281 kN |

|

Overall width:

|

3 mm

|

(Grease) Lubrication Speed

|

45 000 r/min |

|

Rows of Balls

|

Single

|

(Oil) Lubrication Speed

|

53 000 r/min |

|

Outer ring type:

|

Unsplit

|

Load Direction

|

Radial |

|

Radial clearance class

|

CN (Standard)

|

Mass

|

0,0012 Kg |

|

Closure type:

|

ZZ

|

Precision

|

Grade 0 |

Material | Chrome Steel | r min | 0,15 mm |

Cage Material | Sheet Steel | da min | 6,2 mm |

Type of lubrication: | Grease Lubrication | Da max | 9,8 mm |

685 Bearing Short Description

- Miniature ball bearing with smallest dimensions

- Suitable for high radial loads and light axial loads in both directions

- Suitable for high running accuracy, quiet running, and very high speeds

- Seal: contact lip cover on both sides made of metal (ZZ) for high sealing effect

- 685 bearing has good fixed bearing property, but can also be used as a floating bearing, each in both directions

Reasons for The Failure of Miniature Bearings

About 40% of the failures of ball miniature bearings are caused by dust, dirt, debris contamination, and corrosion.

Pollution is usually caused by incorrect use and poor use environment. Therefore, it can also cause torque and noise problems. However, miniature bearing failure caused by environment and pollution can be prevented. And the cause of such failure can be determined through simple visual observation.

As long as the use and installation are reasonable, the erosion of miniature bearings is easy to avoid. Therefore, the feature of erosion is that there are indentations on the raceway of the miniature bearing ring caused by impact load or incorrect installation. Erosion usually occurs when the load exceeds the yield limit of the material.

If the installation is not correct so that a certain load traverses the miniature bearing ring, corrosion will also occur. The pressure pits on the miniature bearing ring can also generate noise, vibration, and additional torque.

685 Bearing Application

Office equipment, micro motors, instruments, laser engraving, small clocks, soft drives, pressure rotors, dental drills, hard disk motors, stepping motors, video recorder drums, toy models, computer cooling fans, currency counters, fax machines, and so on related fields.

- Loading...

- Tel

- *Title

- *Content

Sign up for our newsletter to stay up-to-date with our promotions, discounts, sales, and special offers.

- Deep Groove Ball Bearing

- Ball Screw

- Self-aligning Ball Bearing

- Spherical Roller Bearing

- Thrust Aligning Roller Bearing

- Tapered Roller Bearing

- Thrust Ball Bearing

- Angular Contact Ball Bearing

- Thrust Roller Bearing

- Cylindrical Roller Bearing

- Pillow Block Bearing

- Machinery Equipment

- Thrust Conical Roller Bearing

- Bearing Cage

- Discount and Promotion all bearing

- Steel Balls

- Name:

- Summer Sun

- Tel:

86-0411-88700549

- WhatsApp:

- https://wa.me/8618804285329

- Address:

- No.120 Jinma Road, Dalian Economic And Technological Development Zone, Dalian, Liaoning, China (Mainland)